Thanks to COVID–19, super-duper high-tech manufacturing processes at Micron’s Manassas semiconductor plant are getting even more high-tech.

by James A. Bacon

Will the COVID-19 epidemic inspire the “re-shoring” of manufacturing to the United States and a revitalization of the U.S. manufacturing economy? If so, that could be great news for Virginia communities bet on manufacturing as a source of economic development.

The story is not a simple one. Several commentators in the latest edition of the Virginia Economic Review, published by the Virginia Economic Development Partnership, explore the ramifications of the epidemic for global supply chains and corporate manufacturing strategies. While there is a consensus that corporations will seek to reduce their dependence upon China, the pundits have diverse views on how likely multinational corporations are to repatriate manufacturing operations to the U.S. and what kind of job skills would be required.

Here follows some of the pithier observations and quotes on the topic from the Review.

Elizabeth Reynolds

Executive Director, MIT Industrial Performance Center

“The crisis has exposed the vulnerability of global supply chains and the significant risks involved in sole sourcing from China. Firms are already looking elsewhere toward dual sourcing at a minimum, providing opportunities for rebuilding supply chains in the U.S., particularly for critical healthcare products.” Likewise, Reynolds writes, the crisis has highlighted the value of flexibility and responsiveness in manufacturing, including firms’ ability to ramp up or pivot in response to demand. “There is newfound momentum to improve U.S. manufacturing capabilities through investments in digital manufacturing and more robust regional manufacturing ‘ecosystems.'”

Michelle Comerford

Project Director, Biggins Lacy Shapiro & Co.

“The COVID-19 pandemic has shined a bright light on the fragility of global supply chain networks. … In the U.S., many government officials are calling for the reshoring of manufacturing operations, particularly those that supply and produce essential goods such as pharmaceuticals and medical supplies.” COVID will accelerate an existing trend toward the restructuring of global supply chains, but the process of rebuilding manufacturing ecosystems in the U.S. will be a lengthy one. Moreover, U.S.-based manufacturing will be technology-driven, using artificial intelligence and machine learning, in which automation and robotics will replace more labor-intensive processes. In other words, U.S.-based manufacturing in the future will require require fewer workers and far different skill sets than in the past.

Manish Bhatia

Executive Vice President of Global Operations, Micron Technology, Inc.

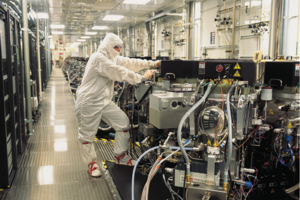

To keep its Manassas semiconductor plant operating through the epidemic, Bhatia says, Micron is relying more than ever upon remote communications to reduce workers’ exposure to the virus. The Manassas plant deployed a Remote Operations Center to reduce the number of production personnel on the factory floor, has figured out how to let workers at home remotely access equipment in the fabrication area, and like many other businesses, is conducting more meetings through video conferencing.

But the impact goes deeper. Micron is using communications technology to re-engineer its processes. “Mobile and augmented reality technologies … help automate and improve end-to-end maintenance workflow processes,” says Bhatia. “This is done by leveraging mobile apps for real-time tool event notifications, maintenance job allocation and execution, and spare parts delivery/replenishment. Remote AR capabilities enable our experts to remotely assist our technicians on the shop floors, to speed up response time and reduce the need for travel.”

Peter Debaer

University of Virginia Darden School of Business

Debaer is less optimistic that the COVID-19 crisis portends a U.S. manufacturing renaissance. “As long as the pandemic was limited to China, it seemed to reinforce the call to bring production back to the United States. Now that the crisis has reached our shores, that view may be changing,” he writes. The U.S. has hardly covered itself in glory for managing the pandemic.

“Reshoring production tends to be viable only for goods that depend on timely delivery or changing customer preferences, or those for which automation can replace offshore production,” he says. “For products that rely on low-skill labor, the significant gains from lower wages and expertise abroad are unlikely to disappear. Multinationals will likely want to retain supply lines abroad to diversify risk and ensure continued production.”